Going rather off-topic for this post, since there has been some curiosity about my slightly odd alternative to the legally-mandated mask. A short version of the back-story here: I don't breath all that well and have trouble with the "used" air inside a mask or face shield, so I was left with the choice of not going anywhere public, going out but declaring a medical condition and trying to keep six feet from people who were more interested in disapproving of me than in keeping their distance*, or making a spectacle of myself by collapsing in public.

So, I started with a face shield -- an acceptable any generally more comfortable alternative to masks -- that my father had for protection against wood chips and other shop accidents. It's gotta be at least 50 years old and is nice and heavy. I've seen lighter face shields, mere sneeze protection probably designed for food service, but those probably wouldn't work for this.

hat gave me as much as an hour, if I didn't do it too often. I needed better ventilation, and decided to try adding a fan somehow. So I hit good ol'

American Science and Surplus' website (which any serious tinkerer and cobbler-together of solutions to non-mainstream problems has bookmarked) and found a

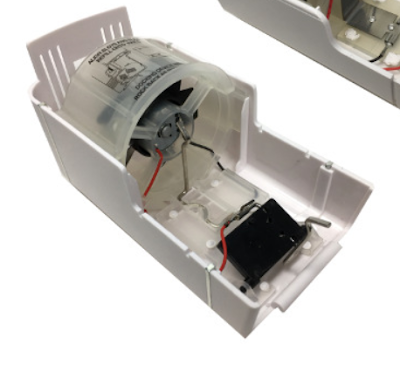

fancy stick-to-the-wall air-stinker-upper with a nice little fan in a case inside.

I used a piece of old VCR cable to extend the wires of the fan, then clipped the fan to the lower edge of the shield with a little binder clip. I settled on running it as an exhaust fan, blowing the used air out (approximately onto my collar, which seems in the spirit of the whole mask idea and anyway made more sense than blowing my exhalations back up my nose) so fresh air comes in from the sides. If I tilt the shield slightly back there's even enough room that it doesn't rub on my chin, although that only matters if I'm going to be wearing it for awhile.

I've had some trouble keeping the battery hooked up to the wires on the other end. It's fine as long as I carry it around in one hand with the wires clamped over the battery terminals, but if I want to use both hands or avoid cramped fingers by taping the wires down and putting the battery in a little bag to stick in my waistband (my clothes tending to lack pockets) it tends to come loose, especially if I move around. I considered soldering wires directly to the battery, but somehow that didn't sound safe; consultation with an electrically-savvy friend confirmed my instinct. She suggested I buy a proper

battery-holder (which I should have realized existed, but didn't), so will do that as soon as my next credit card billing cycle starts.

One of the wires isn't attached to the fan motor as securely as I'd like, so I may dig out the soldering iron after all and add another drop, but I've managed 7.5 hours straight in the thing. It does rather feel like a costume from a bad '60s sci-fi movie or some kind of dry-land helmet diving set-up, but is still an improvement over rebreathing the same air.

-------------

*To clarify, I have great faith in my own immune system and wouldn't bother with all this for myself, but I recognize that not everyone is as unconcerned and I do try not to upset or threaten others.

--------------------------------------------------------------

Addendum...

So, I had my hazmat hood all set up and working well -- and was so proud of it -- when I discovered that the fan was only built for sitting in its little case hanging on a wall, diffusing eau de gas station restroom. It ran for several days and then the wires started to come loose from the back of the fan; I got another day out of it and then one side broke off entirely and I had to slink off in disgrace before my volunteer shift was over.

Well, actually, they were very nice and supportive; Thurston County has an

excellent food bank run by amazingly nice people (especially for how tired they all are these days). I was the only one feeling the need to slink.

Fortunately, I also inherited my dad's soldering iron and... flux? -- I think the stuff on the spool was called flux, but there's also a tube labelled flux in the box of related bits and pieces. Anyway, got the iron plugged in and heating -- it made a horrible smell, having been packed away for decades, but fortunately I was using the stove as my heat-resistant surface so I just turned on the vent fan over it. Then I realized the tip of the iron was almost falling off and had to go find some pliers to screw it back in with (yay me! for thinking ahead and not trying to do it with my bare fingers first, owowow...).

Now, I will post the result here, but keep in mind I've soldered about twice in my life and that was at least 35 years ago and under parental supervision. So yes, it's an ugly, blobby bodge, but I think it'll hold. I could have discarded the little wires entirely and just stuck on the cable ends, but I worried the resultant blobs would run together, so some credit here. Promise not to judge and you can scroll down to see the photo....