After about a month of thumping on that poor hub every time I had a new idea, we finally got it unscrewed and the gears removed. Yay!

I say "we" because it took two of us again. I held the wheel while David wielded the lock ring wrench.

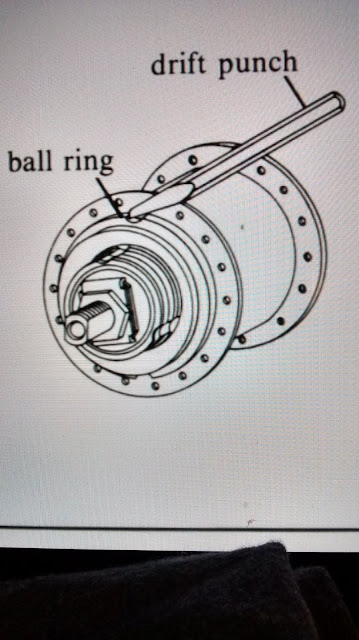

Yep, not the drift punch that all the manuals call for. The drift punch and earlier substitutes weren't transfering enough force to even turn the wheel, and it was almost impossible to get it into the groove without catching the head of the nearest spoke. The wrench allowed us to position the "push points" more precisely and not bounce them around with hammer blows. Actually, the ideal tool would have been a ring with teeth to fit into those grooves and a handle to smack with the hammer, possibly with a cup to screw onto the axle to hold it in place -- like the thing I think of as a "tin can tool" that holds the wrench in place on the bottom bracket, but with a slightly different shape. And maybe another clamp-y tool to keep the wheel from turning. Toolsmithing turned out to be unnecessary (and a good thing, too, since I have neither the tools nor the skill), since I had the use of a large man with strong hands and the right angle for the vise (it's a tad high for me).

And now I get retainer bearings. Except the official parts list says it's a 7 X 1/4" and the one I took out had eight bearings in it. So more research there: did the part change or did someone substitute what s/he had on hand as close enough?

But at least now I can take the hub with me to shop for an index chain without toting the whole wheel all over town.

Oh, and the guy at Deschutes (really should learn their names better, bad me) tells me that what I have is definitely a plain AW hub, not the AW Mark II that I thought it might be. The two little lines stamped on the hub shell are probably an eleven and mean it was made in November of 1964, or, when I was about a year and a half old.

So, here's what I have so far:

20191225

20191213

Freeing Oly's buses!

It's official: all Intercity Transit buses will be free next year. The newest ones are already free; they're not bothering to put fare boxes in them at all. S'posed to be a 5-year experiment, so we'll see how it goes.

I gather they'll be taking the fare boxes out of the older buses, too, as they get to them. In fact, (unofficial but from Someone Who Should Know) the tipping point in the whole argument, which has been in the air for awhile now, was that they can't get the current type of fare boxes anymore, or parts to fix them. Faced with spending millions to upgrade all the buses, they decided to dump the fares instead. Seems it was never that valuable a revenue source anyway.

The drivers are a bit concerned about problem passengers being able to just ride the buses all day, but it seems to me it'll also be easier to kick problems off the bus. Maybe that means just passing them around more, but they'd still be a briefer problem per bus, if you will.

Anyway, we'll find out. I of course hope it'll be wildly successful. It's not even really the money -- $2.50 for a day pass, $36 monthly isn't much of a budget-breaker. It's just a hassle to make sure you've got the right change and trying to guess how much you'll ride the bus next month. Free buses will make impulse trips and getting home in bad weather a lot easier.

So I'm encouraging everyone who supports this move to take the bus to downtown Olympia, where parking is such a problem, and go shopping. The buses will see more riders, and if the downtown businesses see an increase in sales, they'll know this is at least a partial solution to the infamous parking problem. I don't know, am I being too optimistic?

In any case it's a good excuse for a shopping spree, even if I'll only be buying postcards (check out Postcrossing for what I'll do with them). I do plan to go to Lily's to some point in the project, although I may not buy anything there. I love their stuff but I have to feel particularly flush to spend that kind of money (they're not that expensive, I just seldom buy new clothes). Maybe I'll go back in the summer when my power bill leaves me a little extra cash.

BTW, the bike racks on the new buses aren't as bad as they look. If you think ahead and open the hoop bit that goes over your front wheel before loading the bike (it goes all the way around and drops open), you don't even need to make the driver un-kneel the bus. It gives the impression that the bike could roll off backwards, but there's a brace behind the front wheel to prevent that. If you're used to the old racks, it takes a second look to notice it.

I gather they'll be taking the fare boxes out of the older buses, too, as they get to them. In fact, (unofficial but from Someone Who Should Know) the tipping point in the whole argument, which has been in the air for awhile now, was that they can't get the current type of fare boxes anymore, or parts to fix them. Faced with spending millions to upgrade all the buses, they decided to dump the fares instead. Seems it was never that valuable a revenue source anyway.

The drivers are a bit concerned about problem passengers being able to just ride the buses all day, but it seems to me it'll also be easier to kick problems off the bus. Maybe that means just passing them around more, but they'd still be a briefer problem per bus, if you will.

Anyway, we'll find out. I of course hope it'll be wildly successful. It's not even really the money -- $2.50 for a day pass, $36 monthly isn't much of a budget-breaker. It's just a hassle to make sure you've got the right change and trying to guess how much you'll ride the bus next month. Free buses will make impulse trips and getting home in bad weather a lot easier.

So I'm encouraging everyone who supports this move to take the bus to downtown Olympia, where parking is such a problem, and go shopping. The buses will see more riders, and if the downtown businesses see an increase in sales, they'll know this is at least a partial solution to the infamous parking problem. I don't know, am I being too optimistic?

In any case it's a good excuse for a shopping spree, even if I'll only be buying postcards (check out Postcrossing for what I'll do with them). I do plan to go to Lily's to some point in the project, although I may not buy anything there. I love their stuff but I have to feel particularly flush to spend that kind of money (they're not that expensive, I just seldom buy new clothes). Maybe I'll go back in the summer when my power bill leaves me a little extra cash.

BTW, the bike racks on the new buses aren't as bad as they look. If you think ahead and open the hoop bit that goes over your front wheel before loading the bike (it goes all the way around and drops open), you don't even need to make the driver un-kneel the bus. It gives the impression that the bike could roll off backwards, but there's a brace behind the front wheel to prevent that. If you're used to the old racks, it takes a second look to notice it.

20191209

The importance of light

Found the %*#! ball cup and the slot to hammer on to unscrew it!

The instruction drawings and photos led me to expect the ring I was looking for to be right against the next layer in (think that's one of the dust caps), and possibly a step lower. Then, the actual ring was under a thick velvety coat of grime and looked like part of the flange; the seam where the pieces join was completely obscured and the slots were nearly invisible.

What the internet said:

What Glenn's Manual said:

What I actually had:

In better light:

Complicating the issue, my "shop" is actually one end of what's supposed to be my apartment's living room. I'll spare you the full rant about living room design; the bottom line is, most of my working light comes from a forehead-mounted flashlight thing. Once I took the wheel into my actual living room (meant to be the bedroom, with a nice ceiling light and south-facing window) to compare with the photo in the *manual, I could barely see the slots. Next step will definitely be to clean the outside of the hub so I can see what I'm doing.

The instruction drawings and photos led me to expect the ring I was looking for to be right against the next layer in (think that's one of the dust caps), and possibly a step lower. Then, the actual ring was under a thick velvety coat of grime and looked like part of the flange; the seam where the pieces join was completely obscured and the slots were nearly invisible.

What the internet said:

What Glenn's Manual said:

What I actually had:

In better light:

Complicating the issue, my "shop" is actually one end of what's supposed to be my apartment's living room. I'll spare you the full rant about living room design; the bottom line is, most of my working light comes from a forehead-mounted flashlight thing. Once I took the wheel into my actual living room (meant to be the bedroom, with a nice ceiling light and south-facing window) to compare with the photo in the *manual, I could barely see the slots. Next step will definitely be to clean the outside of the hub so I can see what I'm doing.

20191112

Turns out I was wrong

I finally took my project bike's rear wheel down to the Walk N Roll shop to discuss replacing the rim and spokes. The rim is steel and fairly rusty, and I thought the spokes were rusty/corroded too, so I figured this would be a good time to learn wheel-building.

Except the Great Olympia Bike Guru (i.e. David at Walk N Roll) tells me it's more complicated than either of us expected. The wheel has 40 spokes, which makes it a difficult rim to match -- most modern, alloy rims have 32 or 36 spokes. And the spokes aren't corroded, they're galvanized; they're supposed to look like that. On top of that, the rim, while made of the less-desirable-with-rim-brakes steel and sporting significant rust patches, is still structurally OK. It's not as simple as buying a new rim; I'll probably be looking for something off an older bike, plus modern spokes aren't quite the same shape. The flanges on steel hubs are thinner than on alloy ones, and modern spoke shoulders curve more gently, so best-case I'd need spoke washers, which are fiddly and expensive.

So, our verdict: rebuild with the current wheel and keep an eye out for both signs of further rusting on the current wheel and a matching rim, ideally a close enough match to use with the current spokes. A shot of something on the Frame Saver lines inside the rim won't hurt in the meantime.

Still waffling on the paint; now I'm thinking the sleek black or grey look won't really fit the "old-school" fluted fenders and generally chunky look. I wonder if I could mimic the colors and general spotty look of corroded copper or patinaed brass. I like that sort of blue-green you get with old copper, and if some of the original flat gold shows through it won't look that odd. So, hmm.

Still gotta figure out how to "unscrew right-hand ball ring completely and remove the cartridge from the hub shell" so I can get in and fix/grease the gears. I've identified the right-hand, i.e. drive side, ball ring but don't see any way to get ahold of it to turn it.*

Did buy it a new tire, though, now that I know for sure what rim I'll be using. Got pair of medium-cheap Schwalbes, in fact, so I could have a matched pair, because good ol' Deschutes had them in stock and because I really really like the expensive but impenetrable high-end Schwalbe Marathons I have on my beloved Breezer.

--------------------

*"Servicing the Sturmey-Archer AW Wide-Ratio Three-Speed Bicycle Hub" appears to want you to use a hammer and punch to do this, but I really don't see how, and anyway I'm not even surethey're not talking about the split-ring p[art before that, which isn't even mentioned here.

Except the Great Olympia Bike Guru (i.e. David at Walk N Roll) tells me it's more complicated than either of us expected. The wheel has 40 spokes, which makes it a difficult rim to match -- most modern, alloy rims have 32 or 36 spokes. And the spokes aren't corroded, they're galvanized; they're supposed to look like that. On top of that, the rim, while made of the less-desirable-with-rim-brakes steel and sporting significant rust patches, is still structurally OK. It's not as simple as buying a new rim; I'll probably be looking for something off an older bike, plus modern spokes aren't quite the same shape. The flanges on steel hubs are thinner than on alloy ones, and modern spoke shoulders curve more gently, so best-case I'd need spoke washers, which are fiddly and expensive.

So, our verdict: rebuild with the current wheel and keep an eye out for both signs of further rusting on the current wheel and a matching rim, ideally a close enough match to use with the current spokes. A shot of something on the Frame Saver lines inside the rim won't hurt in the meantime.

Still waffling on the paint; now I'm thinking the sleek black or grey look won't really fit the "old-school" fluted fenders and generally chunky look. I wonder if I could mimic the colors and general spotty look of corroded copper or patinaed brass. I like that sort of blue-green you get with old copper, and if some of the original flat gold shows through it won't look that odd. So, hmm.

Still gotta figure out how to "unscrew right-hand ball ring completely and remove the cartridge from the hub shell" so I can get in and fix/grease the gears. I've identified the right-hand, i.e. drive side, ball ring but don't see any way to get ahold of it to turn it.*

Did buy it a new tire, though, now that I know for sure what rim I'll be using. Got pair of medium-cheap Schwalbes, in fact, so I could have a matched pair, because good ol' Deschutes had them in stock and because I really really like the expensive but impenetrable high-end Schwalbe Marathons I have on my beloved Breezer.

--------------------

*"Servicing the Sturmey-Archer AW Wide-Ratio Three-Speed Bicycle Hub" appears to want you to use a hammer and punch to do this, but I really don't see how, and anyway I'm not even surethey're not talking about the split-ring p[art before that, which isn't even mentioned here.

20191025

Nearly ready to paint

Now that the weather's turned and there's no real hope of doing any painting outside until spring, I've finally gotten all the bits off the frame and am ready to give it a brisk sanding and start painting. The cleaning/sanding/roughing up of the existing paint is still to be done, so that'll take some of the winter, along with cleaning the rest of the parts.

The main thing, though, is that I got that obnoxious drive-side bearing cup off at last! Took it back to the Walk N Roll shop and borrowed the correct type of wrench, the tool that screws onto the axle to hold the wrench in place (I should know the correct name, but my brain insists on calling it a "little tin can tool" and nothing else will stick), a normal axle since a cottered one won't work, a hammer, and the vise again. Then it was merely a matter of beating on it until it surrendered and came apart. I'd already given it a good soaking in WD-40 and then oil, but it was pretty corroded into place.

Once again, I was glad I stuck it out and got it apart so I could get in there properly with both a wire brush and steel wool for a thorough cleaning. Plus there's some hope it'll be easier to remove the next time I want to get into the bottom bracket to clean and regrease it.

Current leading notion for paint colors: dark grey with lighter blue-grey lugs and just possibly glow-in-the-dark paint for the edges of the lugs and my little moon-and-paw-print logo, depending on price; with that reflective clear-coat I've already decided to finish off with to follow. But black-and-silver is still in the running....

The main thing, though, is that I got that obnoxious drive-side bearing cup off at last! Took it back to the Walk N Roll shop and borrowed the correct type of wrench, the tool that screws onto the axle to hold the wrench in place (I should know the correct name, but my brain insists on calling it a "little tin can tool" and nothing else will stick), a normal axle since a cottered one won't work, a hammer, and the vise again. Then it was merely a matter of beating on it until it surrendered and came apart. I'd already given it a good soaking in WD-40 and then oil, but it was pretty corroded into place.

Once again, I was glad I stuck it out and got it apart so I could get in there properly with both a wire brush and steel wool for a thorough cleaning. Plus there's some hope it'll be easier to remove the next time I want to get into the bottom bracket to clean and regrease it.

Current leading notion for paint colors: dark grey with lighter blue-grey lugs and just possibly glow-in-the-dark paint for the edges of the lugs and my little moon-and-paw-print logo, depending on price; with that reflective clear-coat I've already decided to finish off with to follow. But black-and-silver is still in the running....

20191012

De-cottering the cranks

It took two of us and hauling the frame down to the Walk N Roll shop, but I finally got those cotter pins out of my cranks and the bottom bracket mostly taken apart. The drive-side bearing cup is still corroded in place, waiting on another trip downtown to borrow another tool, and possibly a mallet, but I'm inside and starting to clean out the layer of dried crud. There's one glob of a substance resembling ear wax, but the rest of the grease is gone. Next step: new bearings and a lot of scrubbing with a wire brush and steel wool, which will be a lot easier and more effective if I can get that bearing cup off.

Anyway, what we ended up doing about the cotter pins was to press them back out with a vise, using a couple of large nuts taped together to make a hollow for the pins to be pressed out into.

Anyway, what we ended up doing about the cotter pins was to press them back out with a vise, using a couple of large nuts taped together to make a hollow for the pins to be pressed out into.

20190923

Into the headset

Finally! got the steering tube out. Apparently the trick is to loosen the stem-expander bolt, unscrew the various rings holding the steering tube in the head tube, and let it hang on the stand for a couple of weeks before smacking it sharply with the handle of a pedal wrench, more in frustration than really trying to knock it loose. Possibly the several whacks with a rubber mallet before letting it hang helped as well, and the occasional tug or twist as I walked past, but it was the pedal wrench that did the trick. Yay!

You may wonder why I bothered, since it functioned just fine, but I'm glad I did. All the bearings were completely dry, with just a rusty-looking patina of what must have been grease once upon a time. It was sort of chalky, with just enough moisture left to stick to the rag and wipe out easily, but I think I caught it before anything got badly worn out. I'll replace the bearings anyway, or at least most of them; some look OK but many are, well, not bright, shiny, and smooth (brinelled?). Plus I think I lost some, unless there are fewer in the bottom bearing cup than in the top. I'm told I can replace the loose bearings with the mind already fixed into a ring, like I'm used to, but I have enough trouble getting headsets to to back together without trying to change things.

And, OK, the main reason I wanted the handlebars/steering tube off was to make the frame easier to paint, 'cause I think I'm going to do that. I don't have anyplace to spray it, though, so I'll probably try brushing the paint in; we'll see how that works out. May end up borrowing someone's garage....

After chatting with David-the-Bike-Guru about paint options, and starting work on a dirty white bike at the Walk N Roll shop, I probably won't go for the white with black or cream with brown color scheme after all. My first impulse was black, which I discarded as not visible enough for what's going to be mostly a winter bike, thinking "if only there were such a thing as reflective black...". Now it seems that might actually be a thing, or black with a reflective clear coat, either of which might look pretty darn, um, pretty. There's also glow-in-the-dark paint, although apparently it doesn't glow for very long; could make for cool accent bits while it lasts, though.

You may wonder why I bothered, since it functioned just fine, but I'm glad I did. All the bearings were completely dry, with just a rusty-looking patina of what must have been grease once upon a time. It was sort of chalky, with just enough moisture left to stick to the rag and wipe out easily, but I think I caught it before anything got badly worn out. I'll replace the bearings anyway, or at least most of them; some look OK but many are, well, not bright, shiny, and smooth (brinelled?). Plus I think I lost some, unless there are fewer in the bottom bearing cup than in the top. I'm told I can replace the loose bearings with the mind already fixed into a ring, like I'm used to, but I have enough trouble getting headsets to to back together without trying to change things.

And, OK, the main reason I wanted the handlebars/steering tube off was to make the frame easier to paint, 'cause I think I'm going to do that. I don't have anyplace to spray it, though, so I'll probably try brushing the paint in; we'll see how that works out. May end up borrowing someone's garage....

After chatting with David-the-Bike-Guru about paint options, and starting work on a dirty white bike at the Walk N Roll shop, I probably won't go for the white with black or cream with brown color scheme after all. My first impulse was black, which I discarded as not visible enough for what's going to be mostly a winter bike, thinking "if only there were such a thing as reflective black...". Now it seems that might actually be a thing, or black with a reflective clear coat, either of which might look pretty darn, um, pretty. There's also glow-in-the-dark paint, although apparently it doesn't glow for very long; could make for cool accent bits while it lasts, though.

20190911

Not that Huffy :(

I looked more closely at that pretty red '70s Huffy, and it's too tall for me. Guess it wasn't meant to be. Only a little too tall, but it wouldn't be comfortable to ride.

However, I did decide to paint the Hercules; just have to decide between simple white with black trim and cable housings, or cream with brown. Do they make sepia housing? And white/light grey tires, eventually.

However, I did decide to paint the Hercules; just have to decide between simple white with black trim and cable housings, or cream with brown. Do they make sepia housing? And white/light grey tires, eventually.

20190904

Towing Thing, test #1

Verdict first: the concept seems workable. The execution... needs work.

I put the wheels back on Herc and used that for the test. You may notice in the photos that my test subject lacks a number of parts, including the saddle and brakes. I tucked some pieces of old excercise mat under the naked clamped rim to give it some protection against bumps.

This set-up works fine while walking the lead bike in a straight line. The primary flaw is that I made the end pieces too long, so that if the clamp gets pulled out of position the slightest bit it rubs against the trailer wheels. Some of this problem might be fixed by using a more rigid tie-down technique -- I used bungies because they were quick and would give me an idea. Really I should just saw off the last inch or so at each corner, though.

Also, the clamp wasn't as stable as I'd hoped, mostly because the floor of my trailer isn't actually flat, it's a sheet of plastic that has started to deform wherever the frame doesn't support it. Again, rigid tie-downs; I'm thinking maybe those heavy giant Twist-Ties I saw at Home Depot....

The tow subject (if you will) tended to rock in the clamp -- proper tires would probably have helped -- which allowed the front wheel* to wobble and even flop far enough to drag sideways. I hope solving the above-mentioned issues will fix this enough, but I may have to come up with a way to brace the handlebars/fork to keep the wheel straight.

----------------------------

* actually the last wheel in the line while towing, but you know what I mean.

I put the wheels back on Herc and used that for the test. You may notice in the photos that my test subject lacks a number of parts, including the saddle and brakes. I tucked some pieces of old excercise mat under the naked clamped rim to give it some protection against bumps.

This set-up works fine while walking the lead bike in a straight line. The primary flaw is that I made the end pieces too long, so that if the clamp gets pulled out of position the slightest bit it rubs against the trailer wheels. Some of this problem might be fixed by using a more rigid tie-down technique -- I used bungies because they were quick and would give me an idea. Really I should just saw off the last inch or so at each corner, though.

Also, the clamp wasn't as stable as I'd hoped, mostly because the floor of my trailer isn't actually flat, it's a sheet of plastic that has started to deform wherever the frame doesn't support it. Again, rigid tie-downs; I'm thinking maybe those heavy giant Twist-Ties I saw at Home Depot....

The tow subject (if you will) tended to rock in the clamp -- proper tires would probably have helped -- which allowed the front wheel* to wobble and even flop far enough to drag sideways. I hope solving the above-mentioned issues will fix this enough, but I may have to come up with a way to brace the handlebars/fork to keep the wheel straight.

----------------------------

* actually the last wheel in the line while towing, but you know what I mean.

Bike-by-bike towing

Ever since I got my trailer last spring, I've been thinking about how to load a bike onto it, or anyway to somehow hitch another bike to mine. In the Olympia area, of course, the best way to get a bike of dubious rideworthiness from one place to another is to throw it on a bus, but I wanted to see if I could do it by myself. So this week I finally built myself a Towing Thing out of scrap lumber that will (I hope) clamp onto a wheel and keep a bike upright and steady enough to be towed. I'll post again once I get ahold of a second bike to test it (the only extra bike I have at home is currently in pieces and anyway lacks a rear tire), but for now here's attempt #1:

Towing Clamp Thing

Please note that this is my starting version. Assuming I actually get this thing working at some point, I'll post a final, revised version with a link from here. See my progress.

materials:

procedure:

1. Work out which boards will be ends and which sides.

Possibly optional, but recommended for better strength/durability: Mark a line straight across each end piece about an inch from the middle, then use the side pieces to mark a second line further from the center. This is going to be a slot into which the sides will fit. At this point you can do something fancy with a router or band saw or something to make a wide groove, but here's a simple hand-tool technique (and they said I was wasting my time watching The Woodwright's Shop; does anybody know if the first couple of seasons are available on DVD anywhere? I should look for it, it was a good show). Make a shallow cut into one side of each end piece where the two lines are marked. They should be the same depth and maybe 1/4-inch deep or a little less. Then use a chisel to shave off the face of the board between the two cuts (at this point, I went in and rooted out my ear plugs, but suit yourself). Test that the side pieces will slot into the groove thus created.

2. Drill two guide holes in the end pieces where the sides will connect. Drive nails into these holes until they just emerge inside the grooves (if you've made grooves). At this point you can apply some glue if you wish (I didn't, mostly because I didn't have anything weatherproof on hand). Stand the first side piece on end, place the end piece over it with the (slot and) nails ready to go into it and, if using a different width for the side pieces, one side lined up so it will sit flat when turned on its side. Drive the nails through.

Before starting the second side, make sure it's lined up so it will make a box with the other piece when finished, then glue/nail it together as above. Allow glue to dry if appropriate.

3. Decide if the bolts will be going between the spokes or around the rim and position your holes accordingly. If between the spokes, the holes should be fairly high and about 1/3 of the way in; if outside the rim, you'll want them lower and quite near the end pieces. Since I was using 2x6s for the side pieces, I opted for between the spokes to make sure the wheel doesn't fall out. Drill holes through one side piece, then stack them together (in what will be their closed position) to drill through the second side. If you have a wheel handy, stick it between the two sides to test your clamp, insert the bolts, realize you forgot to get washers, and secure with the nuts (scrounge up or buy a couple of washers before the ride test unless you decide not to use them). The clamp should be fairly stable and hold the wheel easily.

4. Drill a guide hole at each end of the end pieces and screw in the screw eyes as anchor points. I'm thinking rope or strong twine will probably be better than bungees for attaching the clamp to the trailer, but will have a better idea once I can make a proper trial.

Towing Clamp Thing

Please note that this is my starting version. Assuming I actually get this thing working at some point, I'll post a final, revised version with a link from here. See my progress.

materials:

- 4 boards such as 2x4s or 2x6s, approx 20-26 inches, in matching pairs*

- 4 nails long enough to go through one piece of wood and far enough into another to hold it securely (I used 3-inch ones but would have been happier with 2 1/2-inch ones)

- 2 bolts, approx 6 inches long

- 2 nuts (I prefer wing nuts**) to fit the bolts

- 4 medium screw eyes

procedure:

1. Work out which boards will be ends and which sides.

Possibly optional, but recommended for better strength/durability: Mark a line straight across each end piece about an inch from the middle, then use the side pieces to mark a second line further from the center. This is going to be a slot into which the sides will fit. At this point you can do something fancy with a router or band saw or something to make a wide groove, but here's a simple hand-tool technique (and they said I was wasting my time watching The Woodwright's Shop; does anybody know if the first couple of seasons are available on DVD anywhere? I should look for it, it was a good show). Make a shallow cut into one side of each end piece where the two lines are marked. They should be the same depth and maybe 1/4-inch deep or a little less. Then use a chisel to shave off the face of the board between the two cuts (at this point, I went in and rooted out my ear plugs, but suit yourself). Test that the side pieces will slot into the groove thus created.

2. Drill two guide holes in the end pieces where the sides will connect. Drive nails into these holes until they just emerge inside the grooves (if you've made grooves). At this point you can apply some glue if you wish (I didn't, mostly because I didn't have anything weatherproof on hand). Stand the first side piece on end, place the end piece over it with the (slot and) nails ready to go into it and, if using a different width for the side pieces, one side lined up so it will sit flat when turned on its side. Drive the nails through.

Before starting the second side, make sure it's lined up so it will make a box with the other piece when finished, then glue/nail it together as above. Allow glue to dry if appropriate.

3. Decide if the bolts will be going between the spokes or around the rim and position your holes accordingly. If between the spokes, the holes should be fairly high and about 1/3 of the way in; if outside the rim, you'll want them lower and quite near the end pieces. Since I was using 2x6s for the side pieces, I opted for between the spokes to make sure the wheel doesn't fall out. Drill holes through one side piece, then stack them together (in what will be their closed position) to drill through the second side. If you have a wheel handy, stick it between the two sides to test your clamp, insert the bolts, realize you forgot to get washers, and secure with the nuts (scrounge up or buy a couple of washers before the ride test unless you decide not to use them). The clamp should be fairly stable and hold the wheel easily.

4. Drill a guide hole at each end of the end pieces and screw in the screw eyes as anchor points. I'm thinking rope or strong twine will probably be better than bungees for attaching the clamp to the trailer, but will have a better idea once I can make a proper trial.

20190901

Quick addition

Found out that what I have is a cottered crank and basically you get it apart by whacking it. So I guess I need to whack it harder. But not so hard I damage it, so this is going to be interesting...

Next roadblock...

I finally got the rear fender as cleaned up as it's going to get. It polished up fairly well on the outside, especially once I got the reflector off, but I could only do so much with the heavily rusted inside. I decided not to worry about its little dings -- mostly not noticeable unless you're looking closely -- but did some hand-straightening of the supports and they look much better. I got the reflector off with an adjustable wrench; I think the bolt's not metric, although possibly I just wasn't getting the right angle with a regular one. It had quite a bit of guck trapped under it, so I got rid of that and hit the fender with some more polish. Washing the reflector itself got some water in under the cover, but that popped out and I took the rust remover to the cavity underneath. After some fiddling, I realized the bit of white paper under the cover was the real reflective bit, so since it had gotten wet on top of its rust stains I replaced it with a disk of reflective tape.

Then I had another look at the rear wheel and its fancy hub. Apparently I need a drift punch to remove a ring before I can get into the gear itself, so I'll have to take that down to WNR and use my volunteer privileges to borrow one. Maybe I should make myself a big canvas bag for carrying wheels around.

On the wheel subject: I got the front wheel cleaned up and put back together. Turns out the cotton twill rim tape isn't that odd, just higher-quality than today's normal. When I got to Deschutes and asked for rim tape, they asked if it was for a single-walled or double-walled rim. For double-walled rims you need better tape, for single you can get away with what's basically a big rubber band. I told them it's an older steel rim and guessed it might be double-walled since there are holes in the inside. They told me steel rims are always single-walled and I'd be fine with rubber.

A later web search offered a number of other suggestions, including several layers of electrical tape or strapping tape, but I suspect these would turn out to be more expensive than the rubber (mine was just over $3) as well as needing to be repaired/replaced more often.

Foiled in that direction, I stared on removing the cranks to see if I can clean and service the bottom bracket. There's a weird sideways bolt thing happening there; I got the nut off but can't see how the bolt comes off (if it even does). The head is round so apparently it doesn't unscrew, but tapping it with a rubber mallet didn't (appear to) loosen it. So guess I'll have to consult David-the-Bike-Guru at the end of my next volunteer shift, unless I discover something useful before then.

Then I had another look at the rear wheel and its fancy hub. Apparently I need a drift punch to remove a ring before I can get into the gear itself, so I'll have to take that down to WNR and use my volunteer privileges to borrow one. Maybe I should make myself a big canvas bag for carrying wheels around.

On the wheel subject: I got the front wheel cleaned up and put back together. Turns out the cotton twill rim tape isn't that odd, just higher-quality than today's normal. When I got to Deschutes and asked for rim tape, they asked if it was for a single-walled or double-walled rim. For double-walled rims you need better tape, for single you can get away with what's basically a big rubber band. I told them it's an older steel rim and guessed it might be double-walled since there are holes in the inside. They told me steel rims are always single-walled and I'd be fine with rubber.

A later web search offered a number of other suggestions, including several layers of electrical tape or strapping tape, but I suspect these would turn out to be more expensive than the rubber (mine was just over $3) as well as needing to be repaired/replaced more often.

Foiled in that direction, I stared on removing the cranks to see if I can clean and service the bottom bracket. There's a weird sideways bolt thing happening there; I got the nut off but can't see how the bolt comes off (if it even does). The head is round so apparently it doesn't unscrew, but tapping it with a rubber mallet didn't (appear to) loosen it. So guess I'll have to consult David-the-Bike-Guru at the end of my next volunteer shift, unless I discover something useful before then.

20190826

How many bikes does it take...?

...to be a bike hoarder? I've taken on a second project bike

that is bright and shiny but has a strange (and thoroughly seized-up) 2-cable derailleur.

More photos and the rest of the story later; first I think I'd better invent a bike-to-bike tow hitch.

that is bright and shiny but has a strange (and thoroughly seized-up) 2-cable derailleur.

More photos and the rest of the story later; first I think I'd better invent a bike-to-bike tow hitch.

20190817

General History

Just a quick note about the Hercules Museum website I found while looking for the correct cable routing for mine. Website coverage is mostly pre-WWII and way to early for what I'm doing, but still generally interesting.

20190812

Brakes! No brakes!

Herc hangs there expectantly in the end of the living room I've designated as my shop space -- recognizable by the chunk of blue tarp protecting the carpet and, on the other side of the filing cabinet, my new State Surplus AV cart workbench. The original plan was to do most of my work outside on the patio, among the plants, but the work stand and bike aren't really portable enough and anyway I seem to do most of my work after 10 at night. Guess it's a good thing I splurged last spring and got that forehead-mounted light, because even with all three of the lights in that end of the room turned on I still don't have enough light there.

Anyway, I mostly only work about an hour at a time, mostly because it's not that comfortable a workspace but also because I'm usually supposed to be doing something else instead, but it's hanging there Looking Patient at me, like my father used to do when he got roped into going shopping.

So, for instance, Thursday my goal was to get the rear brake off. It's not in bad shape, but I want to give it a good scrub-over and oil everthing on it that moves, both easier to do off the bike. I couldn't budge it, despite taking the rear rack half off to get a better angle on it, so I oiled the bolt thoroughly and let it sit. Then, since I'd had to remove the bolt holding the seat post in place to get the rack out of the way, I tried to pull that and the seat to see what shape it was in. Couldn't get that either, so gave that a good oiling too and retired in a huff.

Saturday I decided to at least pull the rear rack off all the way and have a go at the fender. That went well enough but I soon realized the brake would have to come off to get the fender free. However, looking more closely at the brake, I realized I'd been going at it from the wrong side. I'd been using a screwdriver on the brake side of things when I should have been going at the bolt tucked away on the other side... for which I needed an 11mm wrench. Didn't know there was such a thing, so will hit a hardware store soon, but for the moment I made do with my new (also State Surplus) adjustable pliers. Worked like a charm, so I decided to have another try at the seat post. In that case, I think it was the oil dripped all around the top; it came free with a couple of twists and a heave, and was in good condition under the mud-brown runny grease/oil it was covered with. The post was in much better shape than the saddle and bracket, which are both pretty rust-spotted underneath, although the saddle looks pretty good from the top.

Meanwhile, I keep looking at those rusty wheels. The rear wheel is fairly rusted but the tire, inner tube, and the rubber strip that protects the inner tube from the spoke ends are all nearly new and must have been replaced (comparatively) recently. The front wheel, however... instead of a rubber strip it has what looks to me like a band of twill tape, which has rotted. The tire was sort of rusted to the rim as well, although it looks decent otherwise. I think the twill tape must have held moisture, because in places it's kind of rusted in place. Will take a wire beush to that and see what can be done, but, well, they're steel rims anyway. There has been some talk of having a wheel-building workshop for the Walk N Roll volunteers, and I've seen a whole Sturmey-Archer 3-speed hub without missing bits on the internet for around $50-$60. I keep thinking how much work I could avoid by building myself new alloy wheels instead of trying to track down a drift punch so I can take the old hub to pieces and clean it -- if it is, in fact, clean-able. And it doesn't have anyplace to attach disk brakes, so I'm pretty much stuck with the rim brakes at least on the front, making alloy wheels a desirable thing in this wet climate. But I'd like to salvage as much of it as I can, partly an economic choice but also just to see if I can. That's part of why I took on the project in the first place, after all.

Anyway, I mostly only work about an hour at a time, mostly because it's not that comfortable a workspace but also because I'm usually supposed to be doing something else instead, but it's hanging there Looking Patient at me, like my father used to do when he got roped into going shopping.

So, for instance, Thursday my goal was to get the rear brake off. It's not in bad shape, but I want to give it a good scrub-over and oil everthing on it that moves, both easier to do off the bike. I couldn't budge it, despite taking the rear rack half off to get a better angle on it, so I oiled the bolt thoroughly and let it sit. Then, since I'd had to remove the bolt holding the seat post in place to get the rack out of the way, I tried to pull that and the seat to see what shape it was in. Couldn't get that either, so gave that a good oiling too and retired in a huff.

Saturday I decided to at least pull the rear rack off all the way and have a go at the fender. That went well enough but I soon realized the brake would have to come off to get the fender free. However, looking more closely at the brake, I realized I'd been going at it from the wrong side. I'd been using a screwdriver on the brake side of things when I should have been going at the bolt tucked away on the other side... for which I needed an 11mm wrench. Didn't know there was such a thing, so will hit a hardware store soon, but for the moment I made do with my new (also State Surplus) adjustable pliers. Worked like a charm, so I decided to have another try at the seat post. In that case, I think it was the oil dripped all around the top; it came free with a couple of twists and a heave, and was in good condition under the mud-brown runny grease/oil it was covered with. The post was in much better shape than the saddle and bracket, which are both pretty rust-spotted underneath, although the saddle looks pretty good from the top.

Meanwhile, I keep looking at those rusty wheels. The rear wheel is fairly rusted but the tire, inner tube, and the rubber strip that protects the inner tube from the spoke ends are all nearly new and must have been replaced (comparatively) recently. The front wheel, however... instead of a rubber strip it has what looks to me like a band of twill tape, which has rotted. The tire was sort of rusted to the rim as well, although it looks decent otherwise. I think the twill tape must have held moisture, because in places it's kind of rusted in place. Will take a wire beush to that and see what can be done, but, well, they're steel rims anyway. There has been some talk of having a wheel-building workshop for the Walk N Roll volunteers, and I've seen a whole Sturmey-Archer 3-speed hub without missing bits on the internet for around $50-$60. I keep thinking how much work I could avoid by building myself new alloy wheels instead of trying to track down a drift punch so I can take the old hub to pieces and clean it -- if it is, in fact, clean-able. And it doesn't have anyplace to attach disk brakes, so I'm pretty much stuck with the rim brakes at least on the front, making alloy wheels a desirable thing in this wet climate. But I'd like to salvage as much of it as I can, partly an economic choice but also just to see if I can. That's part of why I took on the project in the first place, after all.

20190728

Backchaining already

So, I started on the brakes this afternoon. I knew I'd probably need new brake pads, and I was right; the present brake pads were petrified -- although not quite as badly as I expected, they weren't crumbling off yet. Pulled the old pads to take along when I get new ones and discovered that one pad was missing entirely. Guess it's a good thing I decided to wait on test-riding the bike until I can be sure of the brakes.

The brakes themselves seem to be in decent shape, with most of their stiffness being corroded cables (add cables to the shopping list). Oil and a bit of work with a wire brush should do for them, but the brake levers... well, I couldn't get the old cable out of the lever for the front brake. Not sure if the lever's little cable-slot is bent or the cable is just thickened by corrosion. They're pretty rust-spotted anyway, so I'll check prices and what's available these days is a similar style and maybe just replace them as well. Good thing I was expecting to take at least a year on this, it's beginning to look like it'll take that long to finance it.

I'll also be keeping an eye open for a new kickstand; the one on it now tends to collapse given the slightest excuse. I'd like to get one of those cool double kickstands for the Bumblebee, which falls over pretty much whenever it's parked on a hill, or grass, or anywhere at all with the trailer attached... so maybe I can use the old one on Herc without it falling over all the time.

Some more start-condition photos:

The brakes themselves seem to be in decent shape, with most of their stiffness being corroded cables (add cables to the shopping list). Oil and a bit of work with a wire brush should do for them, but the brake levers... well, I couldn't get the old cable out of the lever for the front brake. Not sure if the lever's little cable-slot is bent or the cable is just thickened by corrosion. They're pretty rust-spotted anyway, so I'll check prices and what's available these days is a similar style and maybe just replace them as well. Good thing I was expecting to take at least a year on this, it's beginning to look like it'll take that long to finance it.

I'll also be keeping an eye open for a new kickstand; the one on it now tends to collapse given the slightest excuse. I'd like to get one of those cool double kickstands for the Bumblebee, which falls over pretty much whenever it's parked on a hill, or grass, or anywhere at all with the trailer attached... so maybe I can use the old one on Herc without it falling over all the time.

Some more start-condition photos:

Rear rack...

And a front rack!

Coolest fenders ever?

The whole grip turns to shift

Chain guard, a little bent out of shape

3-speed hub, eventually, I hope

Not sure why there are buckles? on the saddle; more research needed...

20190727

Level 1 bike nerd

After a year as an apprentice wrencher at the Walk N Roll shop, I've "levelled up" to full bike-nerdhood (nerd-dom? nerdness?) by bringing home a backup bike... that doesn't actually work yet. It sort of works -- or will once I tune up the brakes and replace the pads -- but it doesn't shift. The internally geared hub, which I'll be keeping because I'm a big fan of internal gears, is missing not only its cable, but its index chain. So I've got some work ahead of me.

My primary bike is an 8-speed Breezer Uptown with all the bells and whistles, which I love but which weighs as much as a small horse and needs its gears serviced annually (I'm not quite up to doing that myself yet, but maybe next year). That means it spends a week in the shop every January, during which time I'm stuck with the bus to get everywhere (I got rid of my car in 2016; which makes some people treat me oddly, but some people are like that). I'd been thinking about getting a second bike to use during that time and in case of other issues with what I call "the Bumblebee," but I'd been thinking on the lines of a super-light, wide-tired racer sort of thing that would finally make me learn to use derailleurs.

Then someone brought this broken-down 1964 AMF Hercules into the shop, with fluted fenders, a very late-50s-futuristic rear rack, a FRONT rack, and a 3-speed internal hub. And a good deal of exposure to the weather. The guys at the shop were calling it "the Jetsons bike" and trying to justify keeping it, but because of the missing index chain it eventually went into the "donate elsewhere" pile and became available to volunteers. So after a bit of waffling on my part, it came home with me.

My primary bike is an 8-speed Breezer Uptown with all the bells and whistles, which I love but which weighs as much as a small horse and needs its gears serviced annually (I'm not quite up to doing that myself yet, but maybe next year). That means it spends a week in the shop every January, during which time I'm stuck with the bus to get everywhere (I got rid of my car in 2016; which makes some people treat me oddly, but some people are like that). I'd been thinking about getting a second bike to use during that time and in case of other issues with what I call "the Bumblebee," but I'd been thinking on the lines of a super-light, wide-tired racer sort of thing that would finally make me learn to use derailleurs.

Then someone brought this broken-down 1964 AMF Hercules into the shop, with fluted fenders, a very late-50s-futuristic rear rack, a FRONT rack, and a 3-speed internal hub. And a good deal of exposure to the weather. The guys at the shop were calling it "the Jetsons bike" and trying to justify keeping it, but because of the missing index chain it eventually went into the "donate elsewhere" pile and became available to volunteers. So after a bit of waffling on my part, it came home with me.

I'm calling it "Hercules Jetson," or "Herc" for short. Apparently you're supposed to name your bikes when you're a bike nerd....

Subscribe to:

Posts (Atom)